Fabricante líder de equipos industriales

de inspección automática POR VISIÓN ARTIFICIAL

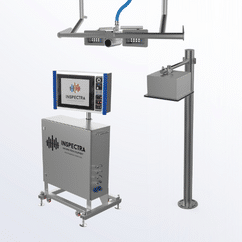

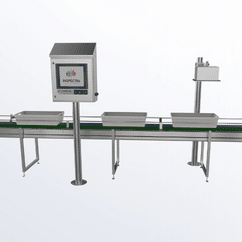

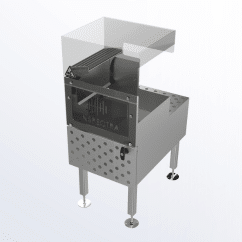

NUESTROS EQUIPOS DE INSPECCIÓN

Descubre nuestro catálogo con todas las soluciones y tecnologías de visión artificial para la automatización de la inspección de calidad:

Soluciones de inspección automática por visión e inteligencia artificial

Somos fabricantes de equipos industriales de visión artificial de automatización de los procesos de inspección de calidad, contando con las últimas tecnologías de visión e inteligencia artificial. Nuestros equipos se integran en las líneas de producción automatizando la retirada de productos que no cumplen con los criterios de calidad, aportando los siguientes beneficios:

- Reducción de costes de personal: Nuestros equipos automatizan las tareas de inspección manual, reduciendo los costes de personal (selección, contratación, formación, gestión, rotación, absentismo).

- Reducción de costes por reclamaciones: Reducimos las reclamaciones de sus clientes: penalizaciones económicas, destrucción de partidas, devoluciones de producto, tensiones con el cliente, imprevistos en producción, etc.

- Contribuimos a la mejora de su OEE

- Digitalizamos el 100% de su producción ofreciéndole datos para una mejora continua de sus procesos y de sus proveedores.

- Trazabilidad y registro de todos los defectos tanto en envases como en producto fresco.

- Alarmas en tiempo real ante desviaciones de calidad en la línea.

- La alta velocidad de inspección de los equipos posibilita aumentar la velocidad de producción de sus líneas.

- Mayor fiabilidad en su inspección de calidad

- Nuestra inspección es objetiva, parametrizable y constante.

- Detectamos defectos de calidad no posibles de detectar en una inspección manual: por tamaño, por velocidad y por transparencia, espectro visual.

- Los mejores rendimientos de inspección del mercado, con tecnología patentada INSPECTRA.

- Velamos por su imagen de la marca ante los clientes más exigentes

- Menores incidencias de calidad de los productos que puedan llegar al consumidor, preservando su imagen de marca.

- Demostrando a sus clientes su compromiso con la calidad al incorporar las tecnologías de inspección más avanzadas del mercado en el proceso de producción.

NUESTRAS TECNOLOGÍAS

HSP®: Visión y procesado a alta velocidad

En algunos de nuestros equipos de inspección como el SLICE INSPECTOR integramos cámaras matriciales de alta velocidad, permitiendo monitorizar procesos que suceden a muchísima velocidad, como el loncheado, en el que se capturan imágenes realizando un seguimiento de la posición de la cuchilla sobre el bloque, determinando los fotogramas en los que no hay oclusión de esta sobre el producto y se puede capturar de forma idonéa la loncha, para procesarla mediante nuestros programas de visión e inteligencia artificial sobre la loncha.

En otros equipos de inspección como el THERMOSEAL INSPECTOR integramos cámaras lineales de alta velocidad que permiten la inspección a una velocidad de 2 envases por segundo, capturando imágenes con diferentes cámaras de alta resolución, tomando la decisión de aceptación o rechazo del envase en unos pocos milesegundos.

Todo esto es posible gracias a nuestra tecnología patentada HSP®que hace uso de la más avanzada tecnología de captura, y mediante nuestro software ISS de procesamiento de las imágenes optimizado para correr en potentes sistemas de computación, sin latencias y con una paralelización de todas las cargas de procesado entre los diferentes hilos del procesador y las GPU.

Esta tecnología permite la toma de decisiones en tiempo real y en línea con los procesos de producción, permitiendo operar las líneas a su máxima velocidad de producción.

EASY AI®: Visión con Inteligencia Artificial

Aplicamos tecnología de Deep Learning en nuestros equipos, la cual constituye una de las bases fundamentales de la Inteligencia Artificial. Esta tecnología se caracteriza por procesar la información a través de diferentes redes neuronales convolucionales entrenadas a medida de cada proceso. Nuestra tenoclogía Easy AI® resuelve clasificaciones complejas imposibles hasta ahora para la algoritmia de visión artificial, como por ejemplo:

- Clasificación de productos

- Segmentación de defectos

- Anomalías en productos

- Conteo

- Lectura de caracteres deformados o entremezclados

La tecnología de Deep Learning permite que el sistema sea capaz de aprender por sí mismo, sin necesidad de programación adicional, mediante una fase previa de entrenamiento a partir de un etiquetado de imágenes, permitiendo la toma de decisiones automatizadas en tiempo real. Los equipos con inteligencia artificial de INSPECTRA tienen un funcionamiento constante, que no depende del operario, realizando la inspección de forma automática, más fiable y más rápida que la humana.

CHP®: Visión hiperespectral e imagen química

La tecnología de visión hiperespectral permite caracterizar los productos mediante técnicas de espectroscopía en línea en el espectro NIR y SWIR, mientras que la tecnología de visión monoespectral utiliza una sola longitud de onda de luz en el rango visible o cercano al infrarrojo.

Nuestra tecnología CHP® realiza un análisis no destructivo de los productos mediante la generación de imágenes químicas en tiempo real. Una imagen química consiste en una representación de un hipercubo en una imagen 2D, en la que a cada firma espectral de un pixel se le asigna un tonalidad de color. Nuestros equipos componen varios modelos de imagen química de forma simultánea y los procesan con nuestra avanzada tecnología de procesado por visión e inteligencia artificial con una tecnología patentada, permitiendo analizar la presencia de cuerpos extraños en línea invisibles para los sistemas de visión convencional y la clasificación de productos en base a criterios de calidad.

Visión de altas prestaciones en el rango visible

Nuestros avanzados algoritmos de procesado de imagen nos permiten llevar al límite los rendimientos de inspección mediante tecnología de inspección en el rango visible RGB/Monocromo. Su integración en nuestros equipos de inspección nos permite obtener unos costes muy ajustados así como un gran rendimiento, resolviendo eficientemente gran parte de las necesidades de inspección de las líneas de producción alimentarias.

NUESTROS CLIENTES